How Can Repiping Improve Low Water Pressure | CPI Service

Low water pressure is a common problem in older homes, often caused by corroded, clogged, or undersized pipes. Homes built before the 1970s, especially those with galvanized steel pipes, accumulate mineral deposits, rust, and scale buildup over time, narrowing the pipe diameter and restricting water flow. This results in weak showers, slow-filling appliances, and uneven water pressure across fixtures, disrupting daily activities.

Repiping solves this problem by replacing old, damaged pipes with modern materials like PEX or copper. These materials have smooth interiors that promote better water flow. PEX resists corrosion and scaling, while copper offers long-term durability and high-pressure tolerance. By upgrading to larger diameter pipes, repiping increases water volume and ensures consistent pressure across all fixtures.

Unlike temporary fixes, such as faucet aerators or booster pumps, repiping addresses the root causes of low water pressure. It eliminates blockages, corrosion, and undersized pipes, providing a long-lasting solution. After repiping, homeowners experience stronger pressure, improved appliance performance, and reduced future maintenance needs.

Table of Contents

How Repiping Fixes Low Water Pressure?

Repiping resolves low water pressure by replacing corroded or blocked pipes, increasing pipe diameter where necessary, and using modern materials like PEX or copper that support efficient water flow and resist future leaks or pressure drops. These upgrades eliminate the root causes of pressure inconsistencies and restore proper flow throughout the system. By addressing both current restrictions and potential long-term issues, repiping delivers stable, reliable water pressure across the entire home.

1. Replacement of Corroded or Blocked Pipes

One of the primary ways repiping restores water pressure is by removing pipes that have corroded or become clogged with mineral deposits. Galvanized steel and cast iron pipes are especially prone to internal rusting, which reduces the pipe diameter and creates friction that limits flow. Over time, calcium and magnesium from hard water build up on the inner walls, compounding the restriction. These obstructions force water through narrower openings, weakening pressure at outlets.

During repiping, technicians cut and remove these degraded lines and replace them with full-bore PEX or copper piping. This restores the system’s intended capacity and enables water to flow freely without blockage.

2. Improved Water Flow Through Larger or More Efficient Pipes

Low water pressure often results from piping that is too narrow or outdated for modern household demand. Repiping corrects this by replacing old 1/2-inch lines with larger 3/4-inch or 1-inch supply lines that can move more water at a given pressure. Larger diameter pipes reduce velocity friction and lower head loss, especially in long runs or multi-story homes.

The material also plays a role in performance. PEX tubing has a lower friction coefficient compared to steel or PVC and can be routed in continuous loops, avoiding sharp turns that slow flow. Together, these changes reduce turbulence and improve flow rates, ensuring stronger, steadier pressure at all fixtures.

3. Prevention of Leaks and Pressure Drops

Another way repiping solves pressure issues is by eliminating weak points in the system where leaks or stress-related failures occur. Older plumbing, especially with threaded joints or deteriorated fittings, often develops pinhole leaks or cracks that bleed off pressure silently over time. These minor leaks reduce system integrity and disrupt steady water delivery.

Repiping uses secure, pressure-tested connection methods, such as copper solder joints or PEX crimp and expansion rings, which form watertight seals with minimal failure risk. With these updated joints in place, the plumbing system maintains internal pressure more effectively, resulting in stable, uninterrupted flow.

4. Ensuring Consistent Pressure Across the Entire Plumbing System

Repiping corrects uneven water pressure by redesigning the system to distribute water more evenly. Older homes often use a series-fed layout, where water must travel through multiple branches before reaching remote fixtures. This setup creates pressure variations when multiple outlets are used at once.

To overcome these limitations, modern repiping often incorporates a manifold or home-run system, where each fixture is connected to the main supply line independently. This updated layout isolates demand at each fixture, preventing pressure drops during simultaneous usage. Whether someone is using a shower upstairs or a dishwasher downstairs, water pressure remains balanced throughout the home.

5. Long-Lasting Water Pressure Improvement

For long-term performance, repiping provides the most stable and sustainable way to maintain strong water pressure. Unlike patchwork fixes that degrade quickly, full-system repiping installs materials designed to resist corrosion, scaling, and deformation over decades of use.

This durability comes from the use of modern piping materials. PEX, with its flexibility and chemical resistance, handles pressure fluctuations without forming cracks or deposits. Type L copper resists high internal pressure and maintains structural integrity even under thermal stress. Combined with optimized flow design, these materials ensure consistent performance and eliminate pressure fluctuations common in aging or patchwork plumbing systems.

Water Pressure Calculator

Enter your details to estimate water pressure improvements and potential savings:

Note:The results provided by this calculator are estimates based on the information entered. Actual water pressure improvements and savings may vary depending on factors such as pipe condition, water quality, and local water pressure regulations. For the most accurate assessment, we recommend scheduling a professional consultation with our team.

Estimated Pressure Improvement: N/A

Potential Savings (Annually): $N/A

ROI (Return on Investment): N/A

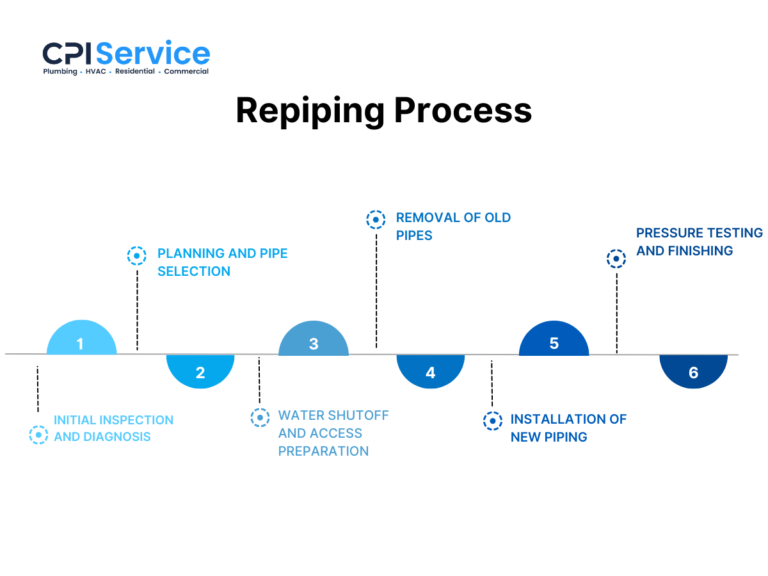

Repiping Process: What to Expect?

Homeowners can expect a carefully planned and minimally invasive process that replaces failing pipes with a new plumbing system designed to improve water pressure, prevent leaks, and deliver long-term reliability. Repiping addresses the root causes of low water pressure, such as corrosion, blockages, and outdated materials, by completely removing the compromised piping network and installing new, high-efficiency lines using proven techniques and durable materials. This solution is not only functional but also strategic, enhancing both performance and property value.

The repiping process typically includes the following steps:

- Initial Inspection and Diagnosis: The process begins with a full system evaluation. Technicians perform static pressure testing, measure fixture flow rates in gallons per minute, and inspect accessible plumbing for signs of corrosion, blockages, or material degradation. If visual access is limited, in-wall pipe cameras are used to locate problem areas without destructive access. This step ensures that every underlying issue affecting pressure is identified before work begins.

- Planning and Pipe Selection: Based on diagnostic results, a complete repiping layout is designed to optimize water distribution. Plumbers calculate required pipe sizes according to fixture unit counts and building dimensions to ensure proper pressure at every outlet. At this stage, materials are selected. PEX is favored for flexibility and resistance to mineral scaling, while Type L copper is ideal for high-pressure, high-temperature zones. Material choice directly affects system longevity and flow performance, making this step essential.

- Water Shutoff and Access Preparation: To begin the actual repiping, the water supply is shut off in isolated zones to minimize disruption. Technicians then prepare access points using targeted cuts in drywall, subflooring, or ceiling cavities. Care is taken to protect interior surfaces with drop cloths and dust barriers, and to contain any moisture using leak sensors or protective wraps. This controlled approach helps preserve the home’s interior during pipe replacement.

- Removal of Old Pipes: Once access is prepared, technicians carefully cut out old galvanized steel, copper, or CPVC lines, using pipe cutters or reciprocating saws. During this step, any incompatible fittings are identified and replaced to avoid future corrosion or pressure irregularities. Old fittings that may have partially collapsed or contributed to the buildup are extracted to restore full flow potential.

- Installation of New Piping: New supply lines are installed along revised, hydraulically efficient routes to reduce run lengths and minimize friction losses. PEX lines are pulled through joists and wall cavities using fish tapes or looped manifold designs, while copper lines are cut and soldered using clean, lead-free flux to meet modern safety standards. All pipes are properly secured with supports or brackets to prevent vibration, expansion, or stress on joints over time.

- Pressure Testing and Finishing: After installation, the entire system undergoes pressure testing, typically between 100 and 120 psi, to ensure all connections are sealed and functioning as designed. Fixtures are checked for balanced flow, and adjustments are made if necessary. Once confirmed, all wall openings are repaired and surfaces restored to their original condition. The final walkthrough includes a performance check and system briefing for the homeowner.

Throughout the process, homeowners can expect minimal disruption, clean and code-compliant installation, and a noticeable improvement in water pressure and flow efficiency. Choosing a licensed professional ensures correct pipe sizing, secure jointing, and optimal system layout, all of which contribute to a durable plumbing upgrade that significantly reduces future maintenance and enhances overall home value.

Choosing the Right Pipes for Repiping

Selecting the appropriate pipe material is one of the most critical decisions in the repiping process, as it directly influences water pressure performance, long-term durability, and installation efficiency. The right material must align with the home’s structural layout, regional water chemistry, and expected usage load. Once the plumbing layout is finalized, professionals evaluate the available plumbing pipe types to determine which will best meet the system’s performance and longevity requirements.

- PEX (Cross-linked Polyethylene): PEX is often chosen for its adaptability in tight spaces and its ability to maintain steady pressure across long runs. Because of its flexibility, it can be installed with fewer fittings, reducing pressure drops caused by elbows and tees. It resists internal scaling from hard water and is freeze-resistant due to its expansion capability. PEX is pressure-rated at 160 psi at 73°F and connects using crimp rings, clamps, or expansion fittings, which speed up installation and minimize leak risks.

- Type L Copper: For projects requiring high structural strength and thermal endurance, Type L copper is the material of choice. It features a thick wall that withstands working pressures up to 400 psi and offers a long service life with low failure rates. Copper’s rigidity ensures straight pipe runs, and its non-porous interior reduces biofilm growth. Installation involves precise soldering with lead-free flux and requires more labor than PEX, but the result is a durable, high-capacity system suitable for both residential and commercial pressure demands.

- CPVC (Chlorinated Polyvinyl Chloride): CPVC is occasionally selected for homes with corrosive water conditions or when copper pricing is cost-prohibitive. It is thermally stable up to 200°F (93°C) and rated for pressures around 100 psi at 180°F (82°C). With its smooth bore and resistance to internal buildup, CPVC supports steady water flow. However, its rigidity makes it vulnerable to cracking under stress or during thermal expansion. Solvent-welded joints also require dry, temperature-controlled conditions to cure correctly, which can extend installation time and introduce variability if not handled precisely.

Long-Term Benefits of Repiping for Water Pressure

Repiping offers a lasting solution to low water pressure by delivering consistent flow, minimizing plumbing complications, extending system durability, and enhancing both efficiency and property resale appeal. These long-term improvements result from upgrading to modern materials and system designs that prevent pressure loss, reduce failures, and maintain optimal flow over time. Homeowners benefit not only from day-to-day performance but also from fewer service calls and increased home value.

Enjoy Consistent Water Pressure Across the House

Repiping standardizes water distribution by eliminating outdated branch layouts and replacing them with pressure-balanced configurations that ensure uniform flow across all fixtures. In older systems, water pressure often drops at distant outlets when multiple fixtures run at once. With repiping, each outlet receives a dedicated or properly routed supply line that prevents flow interference. This ensures that bathrooms, kitchens, and laundry areas all experience steady and equal water pressure regardless of usage patterns.

Minimize Future Plumbing Issues

New piping systems substantially reduce the risk of common plumbing failures by removing corrosion-prone lines and weak connection points. Galvanized and aging copper pipes frequently develop scale buildup, leaks at joints, and structural fatigue over time. Repiping addresses these issues by using modern materials like PEX and Type L copper, which resist chemical corrosion, handle pressure better, and require fewer fittings. This results in a plumbing system that demands less maintenance and experiences far fewer service disruptions.

Increase Plumbing System Longevity

Repiping extends the life of the plumbing system by replacing deteriorating components with materials built to last for decades. PEX offers flexibility and chemical resistance, with an average service life of 40 to 50 years, while Type L copper delivers superior longevity in both high-pressure and high-temperature conditions. These materials also reduce stress on fixtures and valves by maintaining smooth flow and consistent internal diameter. As a result, the entire water delivery infrastructure benefits from prolonged reliability.

Improve Water Flow Efficiency

Modern repiping improves flow performance by enhancing hydraulic efficiency throughout the system. Old pipes often suffer from internal roughness, scaling, and restrictive junctions that reduce water velocity. New materials such as PEX and copper have smoother internal walls that decrease friction loss and support stronger, more direct flow. Technicians also optimize line lengths and minimize sharp bends during installation, which lowers head loss and improves response time at fixtures. This results in faster, more efficient water delivery across the home.

Boost Property Value

Replacing outdated plumbing with a professionally repiped system adds measurable value to a home by eliminating a high-risk structural liability. Potential buyers are more confident in homes with modern water systems that meet current building codes and carry warranties. Repiped homes often pass inspections without issue, reduce insurance concerns, and can command higher offers due to the reduced likelihood of future plumbing expenses. The upgrade not only improves daily functionality but also strengthens the home’s long-term resale position.

Repiping vs Temporary Fixes for Low Water Pressure

While temporary fixes may offer short-term relief at individual fixtures, repiping is the only comprehensive solution that addresses the root causes of low water pressure across the entire plumbing system. Quick fixes like cleaning aerators or adjusting valves can improve isolated flow but fail to resolve system-wide issues like corroded pipes, internal scale buildup, or outdated layouts. Meanwhile, repiping replaces the entire infrastructure with efficient materials and optimized design, ensuring reliable, long-lasting pressure performance.

Key differences between the two approaches include:

- Root Cause Elimination vs Surface-Level Adjustments: Repiping solves the pressure issue at its source by removing constricted, rusted, or scaled pipes that restrict flow. In contrast, temporary fixes such as cleaning aerators or adjusting shutoff valves provide only superficial improvements, with no impact on the deteriorating condition of the underlying plumbing.

- System-Wide Balance vs Localized Fixes: A professionally repiped system is designed to distribute water evenly to all fixtures, maintaining stable pressure even during peak usage. Temporary fixes focus on single outlets, which may slightly improve pressure in one area but leave other zones, like upper floors or distant taps, suffering from continued pressure loss.

- Durable Materials vs Aging Infrastructure: Repiping introduces long-lasting materials like PEX and copper that are engineered to resist corrosion and mineral buildup. Temporary repairs leave old, weakened pipes intact, where existing defects may continue to worsen and eventually lead to leaks or bursts.

- Long-Term Cost Efficiency vs Recurring Repairs: Though repiping has a higher initial cost, it eliminates the need for ongoing maintenance and emergency repairs. On the other hand, relying on temporary fixes often results in repeated service calls and accumulated repair costs without providing a stable resolution.

- Increased Home Value vs Deferred Risk: A home with a new plumbing system is easier to sell, passes inspections more readily, and appeals to buyers seeking long-term reliability. Temporary solutions delay the inevitable, leaving the aging infrastructure in place and creating potential issues during appraisal, sale, or insurance evaluations.

Criteria | Repiping | Temporary Fixes |

Cause Addressed | Eliminates root problems like corrosion, scale buildup, and undersized piping | Only treats surface symptoms like faucet clogging or valve settings |

System Coverage | Improves water pressure across all fixtures with a balanced, efficient layout | Targets isolated fixtures with no impact on overall plumbing performance |

Material Integrity | Uses PEX or Type L copper, which resists corrosion and maintains full bore diameter over decades | Leaves existing aging materials vulnerable to further degradation |

Cost Over Time | Higher upfront cost but lower lifetime maintenance and fewer repair needs | Lower initial expense, but repeated service calls and hidden repair costs add up |

Impact on Property Value | Increases resale value and inspection success due to updated infrastructure | Offers no measurable increase in value and may trigger concerns during resale |

Why Repiping is the Best Long-Term Solution for Water Pressure Problems?

Repiping is the most reliable long-term fix for low water pressure because it replaces corroded, blocked, or undersized pipes with new, high-efficiency materials like PEX or copper. Unlike temporary repairs that only treat symptoms, repiping resolves the root cause and restores steady, full-pressure water flow across all fixtures. It also reduces future plumbing issues and improves system efficiency.

To ensure repiping is done right, homeowners trust professional plumbing services for expert, code-compliant plumbing upgrades. These providers offer professional repiping services for homes and businesses using quality materials, precise layouts, and minimally invasive methods. Licensed teams are experienced in resolving pressure problems caused by aging or faulty plumbing. With expert craftsmanship and dedicated service, homeowners can expect lasting results.

Ready to Improve Your Water Pressure?

Don’t wait for leaks or low pressure to become a bigger issue.

Schedule a free consultation with one of our expert plumbers today to get a customized solution for your home!

- Free, No-Obligation Estimate

- Expert Advice on Material Selection and Process

- Fast and Professional Service

Alex Hamilton

Alex Hamilton is the owner of CPI Service, a trusted provider of plumbing and HVAC solutions. With over 35+ years of hands-on experience in the industry, He brings deep technical expertise and a proven track record in delivering reliable installation, maintenance, and repair services. His leadership ensures that CPI Service consistently upholds the highest standards of quality, safety, and customer satisfaction.