Comparing Trenchless Sewer Repair with Traditional Methods

When sewer lines fail due to age, corrosion, or blockage, property owners often face a critical decision on whether to opt for trenchless sewer repair or use traditional excavation methods. Each method is effective but suited to different conditions. For instance, a homeowner in Sunnyvale may benefit from trenchless repair if the pipe is structurally intact and lies beneath landscaped areas. In contrast, a commercial site in Fremont with a fully collapsed cast iron pipe may require traditional excavation for full access and replacement. Advanced trenchless technologies, such as Spiral Wound Lining and UV CIPP, are also effective for larger diameter pipes or complex shapes.

The impact of these methods varies widely. Trenchless sewer repair is typically faster, less invasive, and minimizes surface disruption. It preserves landscapes, driveways, and sidewalks, making it ideal for urban and residential settings. It is also more environmentally conscious by reducing heavy equipment use and carbon emissions. On the other hand, traditional repair methods, while more invasive, offer complete visibility and flexibility for addressing severe pipe failures, deep obstructions, or non-standard pipe materials.

A side-by-side comparison helps clarify which method fits best based on key factors like repair time, cost, disruption level, and environmental impact. The sections ahead outline how each method performs in these areas to support more informed decision-making.

What is Trenchless Sewer Repair?

Trenchless sewer repair is a modern pipe restoration method that fixes underground sewer lines without the need for large-scale excavation. Instead of digging up entire sections of pipe, plumbers utilize techniques like cured-in-place pipe (CIPP), pipe bursting, and slip lining to rehabilitate damaged lines through existing access points. Trenchless plumbing approach is minimally invasive, preserves landscaping and hardscape, and allows for faster completion compared to traditional methods. It is commonly used in residential, commercial, and municipal settings where reducing surface disruption is a priority.

Other less common techniques, such as pipe reaming or robotic pipe repair, can be considered depending on the specific condition of the pipes. These methods may not always be suitable for every situation, but in cases of minor or localized damage, they may provide a more affordable solution compared to traditional excavation or other trenchless options.

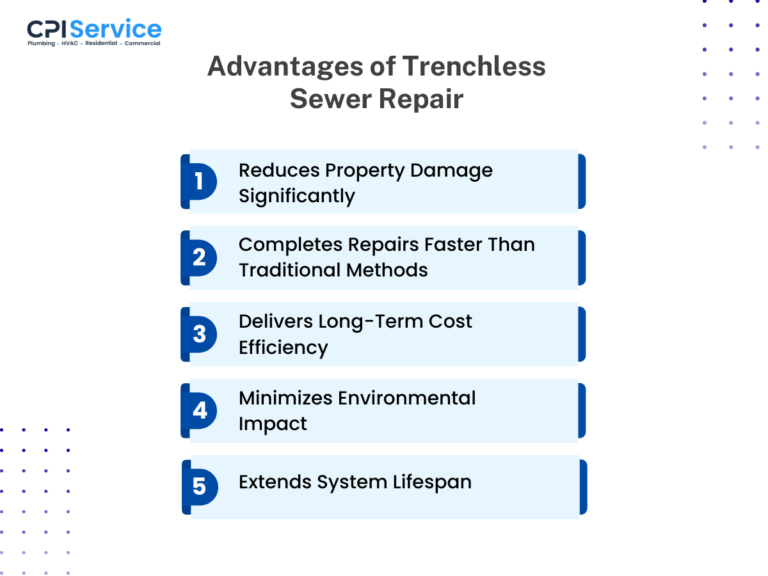

Advantages of Trenchless Sewer Repair

Trenchless sewer repair reduces property damage, shortens repair time, lowers long-term costs, minimizes environmental disruption, and extends the lifespan of sewer systems. It avoids major excavation by preserving lawns, driveways, and sidewalks while completing most repairs within a single day. Additionally, the reduced need for machinery and soil displacement makes it a more sustainable solution for both residential and commercial properties.

Reduces Property Damage Significantly

Using methods such as cured-in-place pipe (CIPP) lining and pipe bursting, trenchless repair technologies rehabilitate sewer lines internally without requiring open trench excavation. These techniques involve inserting resin-coated liners or breaking and replacing old pipes through small entry points, typically at existing cleanouts or access pits. Because there is no need to remove soil along the entire pipe route, surface features like lawns, sidewalks, driveways, and garden beds remain largely undisturbed, reducing both immediate property disruption and post-repair restoration costs.

Completes Repairs Faster Than Traditional Methods

Trenchless methods shorten repair timelines by eliminating time-consuming excavation and backfilling processes required in traditional sewer work. Techniques like pipe bursting and CIPP allow plumbers and technicians to rehabilitate or replace pipes through small access points, often completing the entire process within a single working day. In contrast, traditional methods may take several days due to digging, manual pipe removal, and landscape restoration. The reduced need for heavy equipment and surface disruption significantly speeds up project completion, making trenchless solutions ideal for time-sensitive repairs.

Delivers Long-Term Cost Efficiency

By reducing the need for excavation, trenchless repair minimizes labor, equipment use, and surface restoration, resulting in lower total project costs over time. Advanced materials such as cured-in-place liners and HDPE piping provide long-term durability, resisting corrosion, cracking, and root intrusion. These systems often last 50 years or more, reducing the frequency of future repairs and associated maintenance expenses. The combined savings on manpower, machinery, and post-repair restoration make trenchless solutions a cost-effective investment for both residential and commercial properties.

Minimizes Environmental Impact

Avoiding large-scale excavation helps trenchless sewer repair preserve the surrounding ecosystem by maintaining soil structure, vegetation, and existing surface features. Methods like CIPP and pipe bursting limit surface disruption to small entry points, significantly reducing emissions from heavy machinery and lowering the carbon footprint of the project. Because the process contains wastewater within the pipe system during repair, it also minimizes the risk of contaminating nearby soil or groundwater. Overall, trenchless techniques support more sustainable and environmentally responsible infrastructure upgrades.

Extends System Lifespan

Trenchless repair techniques enhance system longevity by installing seamless, corrosion-resistant materials that outperform older pipe types. Cured-in-place pipe (CIPP) liners bond tightly to existing pipes, eliminating joints where leaks and root intrusions typically occur. Similarly, pipe bursting replaces outdated materials with durable HDPE piping, which is resistant to chemicals, ground movement, and abrasion. These modern systems, when paired with quality materials and proper installation, often carry a lifespan of up to 100 years, significantly reducing the need for future interventions and ensuring long-term reliability.

Limitations of Trenchless Technology

Trenchless repair has limitations, including higher initial equipment costs, the need for proper access, and dependency on the pipe’s condition. While faster and less disruptive, it may not be suitable for severely collapsed or incompatible pipes. The need for specialized tools and skilled crews can increase upfront costs, making traditional methods more practical in certain situations.

High Initial Equipment and Setup Costs

The need for specialized machinery, such as curing systems for CIPP lining or hydraulic systems for pipe bursting, contributes to higher initial costs in trenchless repair. These systems require precise setup and skilled operation, which increases labor costs. Additionally, equipment maintenance and setup for specific pipe conditions can further elevate costs. However, the investment pays off in the long term through reduced labor, minimal restoration needs, and fewer repairs, making trenchless methods more cost-effective over time compared to traditional excavation.

Requires Proper Access and Compatible Pipe Conditions

Trenchless methods require clear access to the sewer line, often through existing cleanouts or manholes, which may not be possible in areas with limited space or deep pipes. Additionally, these techniques depend on the condition and material of the existing pipes. Severely collapsed, misaligned, or non-flexible pipes, such as clay or cast iron, may not be suitable for trenchless repair, requiring traditional excavation. It is important to schedule a pre-inspection to ensure trenchless repair is feasible for your system.

Traditional Methods Still Needed in Certain Situations

While trenchless methods are efficient, traditional sewer repair is necessary for severely damaged or collapsed pipes or when the pipe material is unsuitable for trenchless techniques. For example, pipes that are too deep, misaligned, or have extensive structural issues may require full excavation to provide complete access and visibility for repairs. Professional assessment is essential to determine the best method for your system, ensuring the chosen approach, whether trenchless or traditional, aligns with the pipe’s condition and accessibility.

What is Traditional Sewer Repair?

Traditional sewer repair is a method that involves digging trenches to access and replace damaged or deteriorating pipes. Also known as conventional sewer repair, this method is applicable when pipes are severely damaged, misaligned, or made of materials that are not suitable for trenchless methods, such as clay or cast iron. The process requires excavation, removal or replacement of the affected sections, and backfilling the trench. While disruptive, traditional repair ensures full visibility and control for comprehensive pipe restoration.

Advantages of Traditional Sewer Repair

Conventional sewer repair is ideal for severely collapsed or misaligned pipes, as it provides full access and visibility for thorough repairs. Unlike trenchless methods, it works with all pipe materials, including older or non-standard types like clay or cast iron. This method ensures complete restoration, making it the most reliable solution when trenchless techniques are not feasible due to the condition of the pipe or accessibility issues.

Effective for Severely Collapsed or Misaligned Pipes

When pipes are severely collapsed or misaligned, traditional sewer repair is often the most effective method for addressing the issue. Excavation allows complete access to the damaged sections, ensuring the removal of compromised pipes and replacing them with new, properly aligned ones. This approach is essential for pipes with extensive structural damage that trenchless methods cannot fix. By fully exposing the pipe, traditional repair ensures that the system is restored to its original condition, providing a long-term, reliable solution.

Allows Complete Pipe Access and Visibility

When using the traditional sewer repair, technicians dig up the affected areas to gain direct access to the full length of the pipe, ensuring a more thorough inspection. Unlike trenchless methods that rely on small entry points, excavation provides full visibility of the pipe system. This access is crucial for identifying hidden issues such as cracks, corrosion, and blockages, ensuring no problem is overlooked. The ability to fully assess the pipe allows for a more effective and long-lasting repair solution.

No Dependency on Host Pipe Condition

Excavation-based repairs offer flexibility as they are not reliant on the existing pipe’s condition. While trenchless methods require the pipe to be in good structural shape, traditional method allow for the complete removal and replacement of even the most severely damaged sections. This makes it an ideal solution for pipes that are cracked, corroded, or misaligned. Excavation ensures a full restoration of the system, addressing complex issues that trenchless methods cannot handle, and providing a durable, long-lasting repair.

Compatibility with Older or Non-Standard Pipe Materials

When dealing with older or non-standard pipe materials like clay, cast iron, or concrete, the traditional method is the most effective solution due to the incompatibility of these materials with trenchless repair methods. Trenchless methods typically rely on flexible, modern pipes like PVC or HDPE, which are designed to withstand environmental stresses. Older materials, however, are rigid and prone to cracking or corrosion, making them unsuitable for trenchless repair. Excavation allows for the complete removal of these outdated pipes and their replacement with durable, modern materials, ensuring long-term reliability and system efficiency.

Limitations of Traditional Sewer Repair

Traditional sewer repair comes with several limitations, including longer repair timelines, extensive excavation, and a greater risk of utility interference. The extensive digging required can delay the repair process and damage surrounding utilities like gas or water lines. Additionally, excavation often results in higher restoration costs post-repair, including landscaping and pavement, making it a more disruptive and expensive option.

Longer Repair Timelines

The process of excavating large trenches to access and replace damaged pipes typically results in longer repair timelines. Unlike trenchless methods, which can often complete repairs in a single day, excavation may take several days or even weeks, depending on the complexity and depth of the issue. Weather conditions, the size of the affected area, and the need for permits can all further delay the repair process, making it less efficient and more time-consuming.

Extensive Excavation Required

Excavation for pipe replacement requires digging large trenches, which can disrupt not only the pipe area but also surrounding structures like driveways, sidewalks, and landscaping. This extensive digging can affect property aesthetics, causing significant surface damage that needs restoration. While traditional excavation demands more aggressive digging and increases the overall project scope, the trenchless method uses smaller access points, often eliminating the need for invasive work and property disruption.

Greater Risk of Utility Interference

Using traditional sewer line repair requires large-scale excavation, increasing the risk of damaging nearby utility lines such as water, gas, or electrical cables, which are often buried close to sewer pipes. Accidental ruptures can lead to additional repair costs, service interruptions, and safety hazards. This risk is higher in urban areas where utilities are densely packed. In contrast, trenchless methods minimize this risk due to the minimal digging required, reducing the chance of interfering with utilities.

Higher Restoration Costs Post-Repair

Excavating pipes often causes significant disruption to the property, requiring extensive restoration after the repair is completed. Landscaping, driveways, and walkways are frequently damaged during the excavation process, leading to higher costs for repaving, replanting, and rebuilding. Unlike trenchless methods, which minimize surface disruption and often leave the property untouched, traditional repairs require more extensive post-repair work. This additional restoration significantly increases the total project cost, making traditional repairs more expensive in the long run.

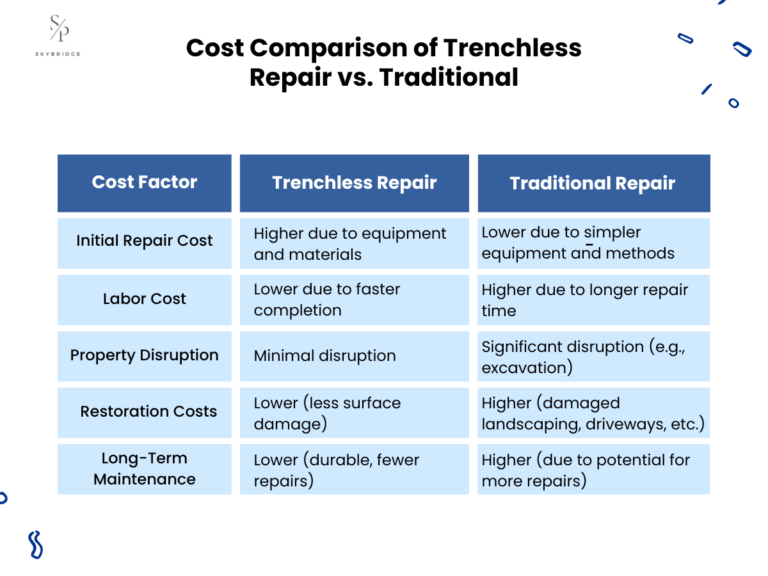

Cost Comparison of Trenchless Repair vs. Traditional

When comparing trenchless repair to traditional sewer methods, there are several cost factors to consider, including initial repair costs, long-term maintenance, and restoration expenses. While trenchless repair often has higher upfront costs due to specialized equipment and materials, it can be more cost-effective in the long run due to faster repairs, reduced property disruption, and fewer restoration needs. Traditional repair, on the other hand, typically involves higher costs for excavation, labor, and post-repair restoration.

Cost Factor | Trenchless Repair | Traditional Repair |

Initial Repair Cost | Higher due to equipment and materials | Lower due to simpler equipment and methods |

Labor Cost | Lower due to faster completion | Higher due to longer repair time |

Property Disruption | Minimal disruption | Significant disruption (e.g., excavation) |

Restoration Costs | Lower (less surface damage) | Higher (damaged landscaping, driveways, etc.) |

Long-Term Maintenance | Lower (durable, fewer repairs) | Higher (due to potential for more repairs) |

Choosing the Right Method for Your Property: Trenchless vs Traditional Method

Choosing between trenchless and traditional sewer repair depends on several factors specific to your property and the condition of the sewer system. Trenchless methods are ideal for properties with minimal surface disruption, where the pipes are accessible and in good condition. However, traditional repair may be necessary for severely damaged pipes or areas with poor access.

To help you decide, consider the following factors:

- Pipe Condition: Trenchless methods are ideal for pipes that are still structurally sound but need repair or replacement, while traditional repair is best for severely damaged or collapsed pipes.

- Property Access: If the area around the sewer line is hard to reach or has limited access points, traditional excavation may be the only viable solution.

- Budget: Trenchless repair may involve higher upfront costs, but can save money in the long term due to fewer disruptions and lower restoration costs.

- Repair Time: Trenchless methods typically offer quicker repairs, often completed within a day, while traditional repairs can take longer.

- Environmental Impact: Trenchless repair minimizes environmental disruption, making it a better option for sensitive areas like landscaped yards or urban settings.

Why Choose Our Sewer Repair Solutions: Trenchless or Traditional Methods?

A professional sewer repair company offers both trenchless and traditional sewer repair methods to provide the most efficient, cost-effective, and minimally disruptive solutions tailored to your property’s specific needs. Whether you are looking for quick, non-invasive repairs using trenchless technology for accessible pipes or need a reliable, comprehensive fix for severely damaged or hard-to-reach pipes with traditional excavation, experienced plumbers ensure the best solution. Contact a trusted sewer repair company today for a consultation to determine the best repair method for your home or business.

Contact us today for a free consultation and let our experts guide you to the best sewer repair solution for your property. Whether trenchless or traditional, we’ll ensure the most efficient and cost-effective approach for your needs.

Get Your Free Consultation

Alex Hamilton

Alex Hamilton is the owner of CPI Service, a trusted provider of plumbing and HVAC solutions. With over 35+ years of hands-on experience in the industry, He brings deep technical expertise and a proven track record in delivering reliable installation, maintenance, and repair services. His leadership ensures that CPI Service consistently upholds the highest standards of quality, safety, and customer satisfaction.