Pros and Cons of Trenchless Pipe Repair

Trenchless pipe repair is an innovative method that allows for the replacement or repair of pipes with minimal disruption to your property. This technique is especially useful for homeowners, businesses, and municipalities dealing with issues like sewer line damage or outdated plumbing systems. By avoiding the need for extensive digging, trenchless repair helps preserve landscaping and hardscaping, offering a more efficient and cost-effective solution compared to traditional excavation.

The main benefits of trenchless pipe repair include minimal property damage, faster repair times, and long-lasting results. Unlike traditional methods, trenchless technology only requires small access points, preserving landscaping and hardscaping. It also completes repairs much faster, often within a day, and the durable materials used extend the lifespan of the pipes.

While trenchless pipe repair offers many benefits, it may not be suitable for severely damaged or collapsed pipes, which require traditional methods. The upfront cost is also higher due to specialized equipment and skilled labor. However, the long-term savings from reduced restoration and fewer future repairs often make it a worthwhile investment.

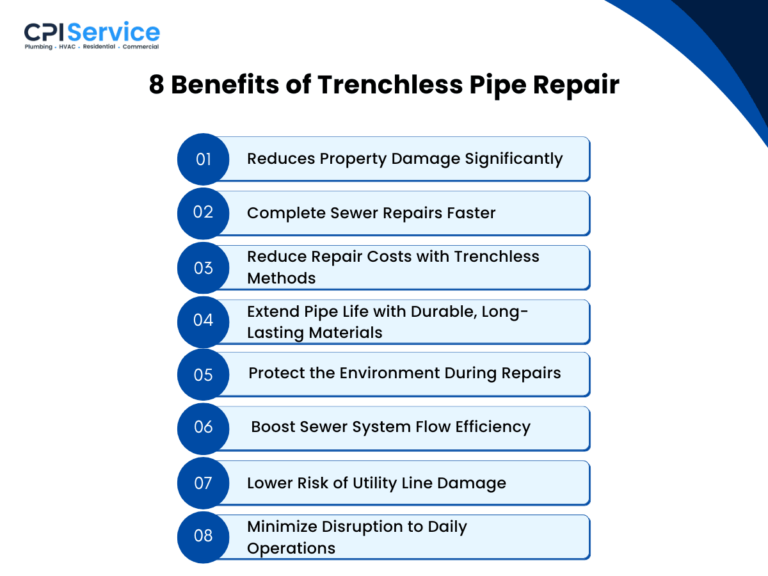

8 Benefits of Trenchless Pipe Repair

Trenchless pipe repair offers a wide range of advantages over traditional methods, providing a faster, more efficient, and less disruptive solution for pipe repair or replacement. Below are the top benefits, each addressing specific challenges that homeowners, businesses, and municipalities often face.

1. Reduces Property Damage Significantly

Trenchless pipe repair is specifically designed to minimize disruption to your property by eliminating the need for large-scale excavation. Unlike traditional methods that require digging up significant portions of your yard or driveway, trenchless techniques only require small entry points, no larger than a few inches, to access the pipes. This approach preserves your landscaping, driveways, and sidewalks, preventing the costly and time-consuming restoration typically needed after traditional repairs. Whether it is a residential property or a commercial site, trenchless repair offers a cleaner, less invasive solution that saves both time and money.

2. Complete Sewer Repairs Faster

Sewer repairs using trenchless methods are significantly faster because they eliminate the need for extensive excavation and post-repair restoration. Traditional methods often require digging up large sections of property, which can take days or even weeks to complete due to the time spent on excavation, pipe replacement, and restoring landscaping. In contrast, trenchless methods like CIPP (Cured-in-Place Pipe) lining only require small access points, allowing repairs to be finished in a matter of hours or within a single day. This efficiency reduces downtime for homeowners and businesses, minimizing the disruption to daily activities and restoring plumbing systems with far less hassle.

3. Reduce Repair Costs with Trenchless Methods

Although the initial cost of trenchless pipe repair may be higher, it reduces overall expenses by eliminating the need for extensive excavation and landscaping restoration. Traditional methods often require large-scale digging, which increases labor and material costs. It also results in costly landscaping repairs to restore driveways, gardens, and sidewalks. In contrast, trenchless methods use small access points, minimizing labor and eliminating the need for costly property restoration.

Additionally, durable solutions like CIPP (Cured-in-Place Pipe) linings, which are resistant to corrosion, roots, and cracks, extend pipe life, reducing the frequency of future repairs and providing significant long-term savings.

4. Extend Pipe Life with Durable, Long-Lasting Materials

Using advanced materials like CIPP (Cured-in-Place Pipe) liners, trenchless pipe repair significantly extends the lifespan of your plumbing system. These liners are specifically designed to resist corrosion, root intrusion, cracking, and other common causes of pipe failure. Made from highly durable materials, CIPP liners create a seamless, corrosion-resistant barrier that strengthens the existing pipes without the need for full replacement. This method restores the original flow capacity of your plumbing while enhancing the overall structural integrity of the system.

With proper installation, trenchless repairs can extend pipe life by up to 50 years, reducing the likelihood of future issues, minimizing maintenance costs, and delaying costly replacements.

5. Protect the Environment During Repairs

Unlike traditional pipe repair methods that involve digging up large trenches, trenchless techniques only require small access points, typically just a few inches wide. This significantly reduces soil disturbance, preventing erosion, contamination of groundwater, and damage to surrounding vegetation, including trees and shrubs. In urban areas, where excavation can disrupt roads, sidewalks, and utilities, trenchless repair methods help preserve infrastructure and avoid costly roadwork or rerouting.

Additionally, trenchless methods use fewer resources and machinery, reducing fuel consumption and emissions, making them a more sustainable and environmentally friendly option for pipe repairs.

6. Boost Sewer System Flow Efficiency

Trenchless methods like CIPP lining not only repair damaged pipes but also enhance the overall efficiency of your plumbing system. These liners create a smooth, seamless interior surface that eliminates rough joints and irregularities, reducing friction and allowing water and waste to flow more freely. This enhanced surface minimizes the risk of clogs and blockages caused by build-up, tree root intrusion, or sediment.

With less resistance, the plumbing system operates at optimal capacity, reducing the need for frequent maintenance or costly repairs. The smoother flow reduces wear and tear on the system, preventing future disruptions and improving the long-term performance of sewer lines, which can extend their lifespan for several decades.

7. Lower Risk of Utility Line Damage

Trenchless plumbing lowers the risk of utility line damage by drastically reducing the need for large-scale excavation. Unlike traditional methods that require large trenches, trenchless techniques use small access points, typically only a few inches wide, to reach the pipes. This precision prevents damage to nearby gas, water, or electrical lines.

Advanced methods like horizontal directional drilling (HDD) and pipe bursting allow for targeted repairs with minimal disruption. In densely populated areas, where underground utility systems are complex and interconnected, trenchless plumbing ensures safer repairs and reduces the likelihood of costly service interruptions.

8. Minimize Disruption to Daily Operations

The main reason trenchless pipe repair minimizes disruption is its ability to eliminate large-scale excavation. Traditional methods require digging up significant portions of your property, causing days or even weeks of disruption. In contrast, trenchless techniques only need small access points, enabling repairs to be completed quickly, often within hours or a day.

For homeowners, this means minimal inconvenience, and businesses can continue operations without interruption, avoiding lost revenue. Whether it is a residential or commercial property, trenchless methods ensure a fast, clean repair, allowing daily activities to resume almost immediately without the extensive mess of conventional digging.

Disadvantages of Trenchless Pipe Repair

Despite its many benefits, trenchless pipe repair has some drawbacks, including the risk of hidden pipe damage, the need for specialized equipment, and its limited use for severely damaged pipes. Also, the upfront cost is higher than traditional methods, though long-term savings may compensate. These factors should be considered when deciding if trenchless repair is right for your needs.

1. Risk of Hidden Pipe Damage

A major drawback of trenchless pipe repair is the potential for undetected internal pipe damage that could compromise the effectiveness of the repair. While trenchless methods like CIPP lining focus on the visible exterior condition of the pipe, issues such as internal cracks, corrosion, root intrusion, or sediment buildup often remain hidden. These concealed problems can lead to incomplete repairs, as they might affect the integrity or flow of the pipe. Without a thorough pre-repair inspection, these issues may go unnoticed, causing the pipe to deteriorate further and requiring additional repairs or even a full replacement down the line.

2. Requires Skilled Equipment and Technicians

The success of trenchless pipe repair heavily relies on specialized equipment and highly skilled technicians. Techniques like horizontal directional drilling (HDD) and pipe bursting involve complex machinery that requires precise handling. If not properly operated by trained professionals, these advanced methods can lead to faulty repairs or even damage the existing pipeline. The level of expertise required to correctly execute trenchless repairs means that technicians must be well-trained, and the equipment needs regular maintenance, which can increase the overall cost and complexity of the repair process.

3. Unsuitable for Severely Damaged Pipes

Trenchless pipe repair is not always suitable for pipes that are in severely damaged or compromised conditions. If the pipes have collapsed, cracked extensively, or suffered significant structural damage, trenchless methods may not be effective. In these cases, traditional excavation and complete pipe replacement might be necessary to ensure proper functionality. Trenchless repair methods rely on the pipe’s existing structure to facilitate the repair process, and severely damaged pipes cannot always support the installation of a new lining or replacement.

4. Higher Upfront Cost Than Traditional Repair

While trenchless pipe repair offers long-term savings, it typically comes with a higher initial cost compared to traditional pipe repair methods. The need for specialized tools, materials, and skilled labor can make trenchless repair more expensive upfront. This can be a barrier for some homeowners or businesses, particularly when the problem is relatively minor. While the lower restoration costs and durability of trenchless repairs can lead to overall savings, the higher initial expense may not be justifiable for every situation, especially when traditional methods could be sufficient.

Why Hiring a Professional Is Essential for Trenchless Pipe Repair?

Hiring a professional for trenchless pipe repair is essential due to the complexity and precision required throughout the process. Trenchless methods, such as CIPP lining and horizontal directional drilling (HDD), involve complex machinery and materials that demand precision. Without professional experience, there is a risk of misalignment or improper installation, which can lead to leaks and costly repairs. Professionals ensure accurate inspections, proper equipment use, and high-quality work, guaranteeing long-lasting, effective repairs.

Alex Hamilton

Alex Hamilton is the owner of CPI Service, a trusted provider of plumbing and HVAC solutions. With over 35+ years of hands-on experience in the industry, He brings deep technical expertise and a proven track record in delivering reliable installation, maintenance, and repair services. His leadership ensures that CPI Service consistently upholds the highest standards of quality, safety, and customer satisfaction.