Free HVAC Maintenance Checklist: Essential Tasks to Keep Your System Running

Taking care of an HVAC system involves various tasks like checking air filters, cleaning coils, inspecting thermostats, and monitoring refrigerant levels, which can feel overwhelming when trying to keep everything working properly. A simple HVAC maintenance checklist simplifies these tasks by showing what needs attention and when, ultimately helping you ensure consistent airflow, heating, and cooling throughout the year.

An HVAC maintenance checklist also organizes routine steps that reduce sudden system failures and improve energy efficiency. For instance, when filters, coils, and vents are regularly cleaned, strain on the compressor is reduced. Such regular maintenance methods reduce breakdowns by 70% to 75% according to researchers from the LMAID laboratory and Green Energy Park in Morocco.

Commercial buildings and homes also benefit from an HVAC maintenance checklist that keeps track of monthly and seasonal tasks like refrigerant checks, coil cleaning, and thermostat calibration. These steps help HVAC systems perform consistently, and equipment with regular care can last up to 40% longer than neglected units.

What Is an HVAC Maintenance Checklist?

An HVAC maintenance checklist is a clear list of tasks that helps keep heating, cooling, and ventilation systems running smoothly year-round. It helps homeowners and commercial property managers stay organized by outlining the steps to inspect and clean core parts like filters, coils, vents, thermostats, and refrigerant lines. The checklist also helps to know when parts need replacement, helping to keep the system operational for 40% longer than those that go neglected. Following this HVAC maintenance checklist prevents recurring issues, reduces power usage, and supports steady airflow and heat exchange, while making sure essential monthly and seasonal maintenance tasks are never missed.

Why Is the HVAC Maintenance Checklist Important?

An HVAC maintenance checklist helps homeowners and property managers stay organized by laying out the steps needed to keep HVAC equipment running smoothly. It supports steady performance in homes and commercial buildings by keeping routine care on track and ensuring the system receives the right amount of attention.

9 core benefits of an HVAC maintenance checklist are:

- Repair cost savings: Regular inspections catch small issues early, preventing costly repairs.

- System efficiency: Cleaning coils, filters, and vents improves airflow and heat exchange, reducing strain on the HVAC system.

- Safety and reliability: Planned inspections identify electrical, gas, and airflow issues before they become hazards.

- Energy savings: Scheduled maintenance reduces energy use through proper cleaning and calibration.

- Avoid breakdowns: Completing cleaning and inspection tasks on time reduces the risk of sudden failures.

- Longer lifespan: Regular care reduces wear on components, helping the equipment last longer.

- Better indoor air quality: Cleaning filters and coils removes dust and pollutants, which lead to fresher indoor air.

- Warranty compliance: Documenting maintenance tasks helps meet manufacturer service requirements and keep warranties valid.

- Peace of mind: A clear schedule ensures consistent care, giving homeowners and property managers confidence that the system works properly.

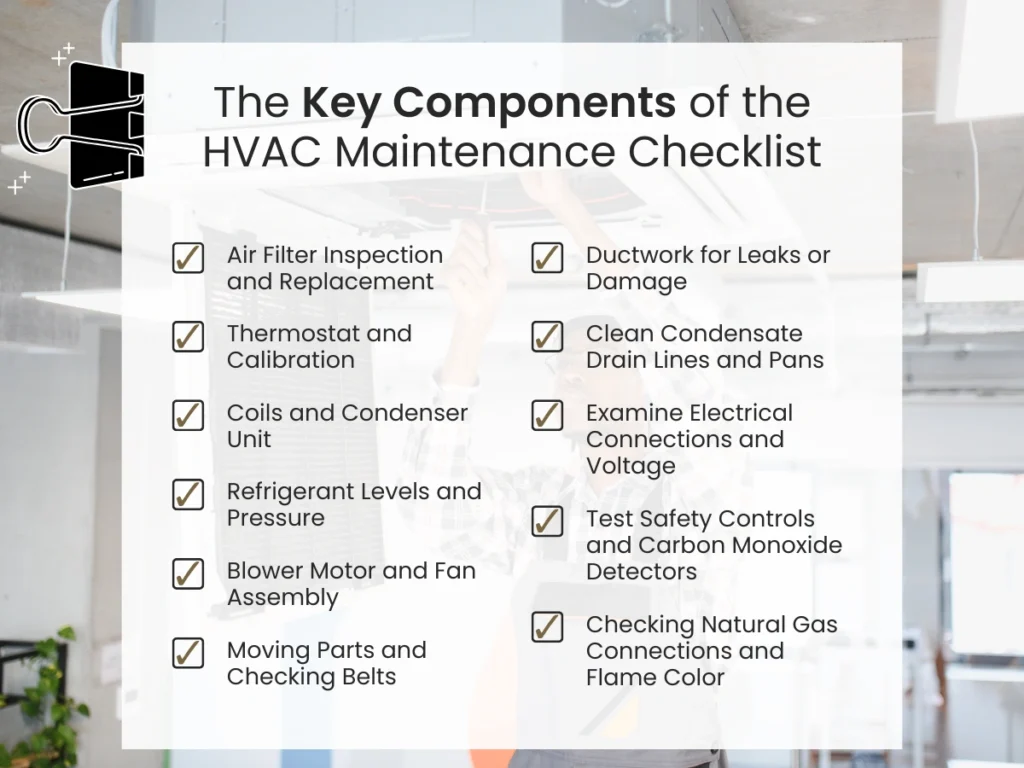

What Are the Key Components of the HVAC Maintenance Checklist?

A complete HVAC maintenance checklist covers important tasks like checking air filters, cleaning coils, inspecting thermostats, reviewing refrigerant levels, and examining ductwork for leaks. These steps keep the system operating safely without interruptions and help maintain steady airflow, heating, and cooling in homes and large commercial buildings. The sections below explain each of these components so you can understand what they do and why they matter.

Air Filter Inspection and Replacement

Air filters must always be kept clean, as they support clear indoor airflow and reduce strain on the system by keeping air passages open. Regular inspection of HVAC units also prevents heating and cooling equipment from working harder than needed, which keeps energy use under control.

- Always turn off the HVAC unit before inspecting or removing the air filter from its slot.

- Inspect the filter every month, and if you notice dust buildup or clogs that block airflow, replace it.

- Inspect filters more often if heating and cooling systems are used heavily in dusty or high-traffic areas.

- Clean surrounding vents by wiping or vacuuming to keep air paths clear.

- When replacing, check that the new filter size and rating match your HVAC system.

- Check for gaps around the filter slot that may allow unfiltered air to bypass the system.

- Install the new filter with the airflow arrow pointing in the correct direction.

Thermostat and Calibration

A thermostat reads the room temperature and signals the HVAC system to heat or cool as needed. If the reading of the actual room temperature is inaccurate, the system heats or cools the space too much or too little, leading to uncomfortable temperatures and higher energy use.

- Measure room temperature by placing a room thermometer next to the thermostat for 15 minutes, then compare the readings.

- Turn off the HVAC system and remove the thermostat cover if the reading is off by more than 3°F.

- Gently clean dust from sensors and interior components using a soft brush or cloth.

- Adjust calibration using the calibration screw on older mechanical units or the offset setting on digital units.

- Make small calibration adjustments until the thermostat reading matches the thermometer.

- Place the thermostat away from vents, sunlight, and appliances that affect temperature readings.

- Put the cover back on, turn on the power, and re-test the readings to confirm calibration.

- Replace it if the readings are still off, or contact the manufacturer if the warranty is valid.

Coils and Condenser Unit

Coils move heat out of the system during cooling, but dirt buildup can interrupt the heat transfer. A clogged condenser unit limits airflow, reducing cooling efficiency and raising energy costs.

- Turn off the system’s power at both the thermostat and the breaker.

- Clear all debris from around the outdoor condenser to keep airflow open.

- Remove the condenser unit’s outer cover to access the coils and fan.

- Remove loose debris from the interior and bottom of the unit using a soft brush or vacuum.

- Apply a foaming or non-caustic coil cleaner to the coils and allow it to sit for 5 to 10 minutes.

- Rinse the coils with low-pressure water (garden hose), working outward through the fins to wash away debris.

- If there are bent fins, straighten them with a fin comb to allow proper airflow.

- Leave out the coils until they dry. Then reassemble the condenser cover and turn the power back on.

- Turn the thermostat back on and confirm the cooling system works properly.

Refrigerant Levels and Pressure

Refrigerant absorbs heat and moves it outside to provide cooling, but if levels are low or pressure is out of range, the HVAC system cannot cool properly, putting strain on the compressor. They can also lead to costly repairs and environmental damage.

- Turn off the HVAC system and locate the service panel on the outdoor unit to access refrigerant ports.

- Attach HVAC gauges to the high-pressure and low-pressure service ports.

- Compare pressure readings to the manufacturer’s recommended range for your system.

- Check for warm air at vents, ice on the evaporator coil, or hissing sounds that indicate a low refrigerant level.

- Inspect refrigerant lines for oil marks, which often signal a leak.

- Secure the thermal expansion valve and sensing bulb, and ensure they are not blocked by dirt.

- Contact a licensed HVAC technician if pressure is unsafe. Do not add refrigerant yourself.

- Reapply the service port caps and restore power to confirm a normal cooling cycle.

Blower Motor and Fan Assembly

The blower motor and fan move air through the HVAC system, but dust buildup, loose parts, or wear can disrupt airflow, forcing the system to use more energy to work. Maintaining smooth airflow, preventing system strain, and avoiding premature failure requires regular maintenance.

- Turn off the power to the HVAC system before inspecting the blower compartment.

- Remove the access panel on the air handler to reach the blower motor and fan.

- Look for dust buildup on fan blades and clean them with a soft brush or cloth.

- Look for physical damage and spin the fan wheel by hand to check for stiffness, creaking noise, or wobbling.

- Inspect wiring and connections for loose or damaged components like the capacitor.

- Listen for grinding or squeaking noises that indicate the blower motor needs servicing.

- Properly balance and align the blower wheel inside the housing.

- Turn the power back on and confirm that airflow from vents is steady.

Moving Parts and Checking Belts

When moving parts like motors, bearings, or belts dry out or wear down, the HVAC system works harder, causing weaker airflow and higher energy use. Lubricating these parts and checking the belt condition helps the system run steadily.

- Turn off the system’s power before accessing the blower area or motor housing.

- Locate motor bearings and fan shafts.

- Apply lubricant to bearings or ports and wipe away excess liquid.

- Inspect belts for cracks, fraying, or glazing that may further affect airflow.

- Press gently on the belt to check its tension and adjust if it is too loose or too tight.

- Confirm that the pulleys are aligned so the belt runs smoothly without slipping.

- Restore power and listen for creaks or other sounds that may signal persisting issues.

Ductwork for Leaks or Damage

Ductwork carries hot and cold air through the building, and any gaps, tears, or loose joints can cause air leakage, causing up to 30% of air to be lost. This forces the HVAC system to work harder and increases energy use.

- Look for visible holes, cracks, or loose connections along duct sections that are easily accessible.

- Drag a tissue along the duct seams while the power is on, and see if it is moved by escaping air.

- Check for disconnected or sagging duct sections in attics or basements using a flashlight.

- Inspect insulation around ducts for damage.

- Seal small gaps with duct mastic or aluminum foil to prevent air leaks.

- Apply foil tape on seams that need a stronger hold than standard tape.

- Check for leaks in inaccessible areas using a flexible inspection camera.

- Recheck the supply and return vents to confirm they are open and unobstructed.

Clean Condensate Drain Lines and Pans

Condensate drain lines remove moisture produced during cooling, and when they clog, water can back up into the system and cause leaks, mold, and humidity. A blocked drain pan or algae buildup can trigger safety switches that shut off the HVAC system.

- Turn the power off and locate the condensate drain line near the indoor air handler.

- Check the drain pan for still water, dirt buildup, or algae growth.

- Use a wet-dry vacuum on the drain line outlet to remove blockages.

- Pour a cleaning solution like diluted vinegar into the drain line to clear remaining buildup.

- Clean the drain pan with a mild cleaner like condensation pan treatment chemicals to remove dirt and prevent mold formation.

- Inspect the drain line for cracks or loose fittings that could cause water leaks.

- Turn on the power and confirm that water flows freely through the drain line.

Examine Electrical Connections and Voltage

Bad electrical connections and incorrect voltage can cause HVAC systems to short-cycle, lose power, or stop running altogether. Simple visual checks are safe for homeowners, but deeper voltage testing requires trained HVAC technicians, as electric shocks can be fatal.

- Shut off power to the HVAC system before inspecting or touching any electrical parts.

- Remove the access panel and look for loose or corroded terminals, burned wires, and damaged insulation.

- Tighten loose terminal screws using proper tools and confirm that spade connectors are seated properly.

- Verify that wiring is routed cleanly and is not pinched or broken.

- Set a multimeter to AC voltage to confirm proper readings at the 240V transformer or the 120-240V power supply if you are fully trained. If not, contact a professional.

- Look for low or inconsistent voltage, which may indicate a weak transformer or poor connection.

- Perform continuity checks using a multimeter to confirm that wires are intact and that electricity can flow through them.

- Restore power and check that the system starts smoothly without irregular cycling or flickering lights.

Test Safety Controls and Carbon Monoxide Detectors

In-built safety controls protect the HVAC system from overheating or unsafe burner operation, and carbon monoxide detectors alert you to harmful gas buildup. If either fails, the system may keep running even when it is supposed to shut down, creating serious risks.

- Press and hold the test button on your carbon monoxide detector to confirm the alarm sounds properly.

- Replace batteries if the alarm does not sound. If it still fails, full unit replacement may be needed.

- Replace detector batteries every six months, even if the unit appears to be running smoothly.

- Install detectors at least ten feet away from fuel-burning equipment.

- Check the detector’s expiration date and replace it if it is past its rated service life.

- Contact a professional to verify that safety switches activate correctly under unsafe conditions.

- Call a technician for advanced carbon monoxide testing and all safety control checks.

- Restart the system after testing and confirm that all safety controls operate normally.

Checking Natural Gas Connections and Flame Color

For heating systems to operate safely, natural gas connections must stay tight and leak-free. A furnace flame should be bright blue, and orange or yellow flames signal poor combustion, soot buildup, or a gas leak.

- Turn off the heating system and visually inspect gas lines for dents, cracks, or corrosion.

- Apply a soapy water solution to accessible gas fittings and see if bubbles form, as this indicates a leak.

- See the furnace flame through the burner window and confirm it burns a bright blue color.

- Note any yellow, orange, or flickering flames that indicate a combustion or venting issue.

- Clean dust or debris from the burner area.

- Check the pilot flame for stability and strength, if a pilot assembly exists.

- Turn off the system and contact a licensed HVAC professional if you suspect a leak or see abnormal flame colors.

What Are the Best Practices of Using an HVAC Maintenance Checklist?

The best practices for using an HVAC maintenance checklist include organizing tasks, adhering to a clear schedule, and performing timely inspections to ensure optimal airflow, energy efficiency, and system performance year-round. This approach helps property owners stay organized, ensures regular attention to the system, and prevents missed maintenance steps that could impact comfort and efficiency in both homes and commercial buildings.

8 best practices of using an HVAC maintenance checklist are as follows:

- Use the HVAC maintenance checklist at the start of every season to prepare the system for temperature fluctuations.

- Follow monthly filter inspection and airflow checks to prevent dust buildup and maintain efficient heating and cooling.

- If HVAC operates heavily in dusty or urban areas, inspect them once every two weeks.

- Record each completed task so future inspections are accurate and easy to follow.

- Adjust the HVAC maintenance checklist based on the age of the system, size of the building, and usage patterns.

- Include both indoor and outdoor tasks so the entire system receives attention.

- Review the HVAC maintenance checklist before high-demand periods such as summer cooling or winter heating, and increase the inspection frequency.

- Call a licensed technician if you find issues beyond basic cleaning or visual inspection and gas or electricity-related problems.

Ensure Peak Performance With Professional HVAC Maintenance Checklist

A professional HVAC maintenance checklist offers a more thorough inspection than typical homeowner checks, addressing aspects that are often overlooked in basic DIY maintenance. Certified HVAC technicians use specialized equipment to measure refrigerant pressure, test electrical components, and evaluate airflow, tasks that go beyond the capabilities of DIY methods. These in-depth assessments help ensure that HVAC systems operate efficiently, maintain stable performance, and increase their longevity in both residential and commercial environments.

Key tasks on a professional HVAC maintenance checklist include cleaning coils, testing safety controls, inspecting ducts, and adjusting components. These actions are critical for optimizing heat exchange, preventing system failures, and improving overall system efficiency. Regular expert maintenance, performed by a licensed HVAC contractor, maintains safety, enhances energy efficiency, and ensures reliable comfort across seasons, making it a crucial investment for both homeowners and property managers.

Alex Hamilton

Alex Hamilton is the owner of CPI Service, a trusted provider of plumbing and HVAC solutions. With over 35+ years of hands-on experience in the industry, He brings deep technical expertise and a proven track record in delivering reliable installation, maintenance, and repair services. His leadership ensures that CPI Service consistently upholds the highest standards of quality, safety, and customer satisfaction.